The electric vehicle (EV) industry is witnessing rapid growth, driven by the global shift toward clean energy and sustainable transportation. Among the critical components contributing to the efficiency and performance of electric vehicles, insulation technology plays a pivotal role. The electric vehicle insulation market has thus become increasingly important in ensuring the safety, performance, and longevity of EVs, while also improving energy efficiency. Recent developments in this sector highlight significant advancements in material technologies, manufacturing processes, and industry standards, all of which aim to enhance the EV driving experience.

Growth Drivers in the Electric Vehicle Insulation Market

The growth of the EV insulation market is driven by several key factors. Primarily, the increasing demand for electric vehicles, fueled by government incentives, stricter environmental regulations, and growing consumer awareness about climate change, has made insulating materials more critical. As EVs rely on high-performance batteries and electric drivetrains, effective insulation is essential for minimizing heat loss, ensuring efficient power consumption, and enhancing overall safety.

Another key driver of this market is the rising adoption of advanced insulation materials that can withstand the unique demands of electric vehicles, including extreme temperatures and high voltage environments. Insulation materials not only protect the vehicle’s electrical components from external influences but also ensure that passengers remain safe from electrical hazards.

Recent Developments in Electric Vehicle Insulation Materials

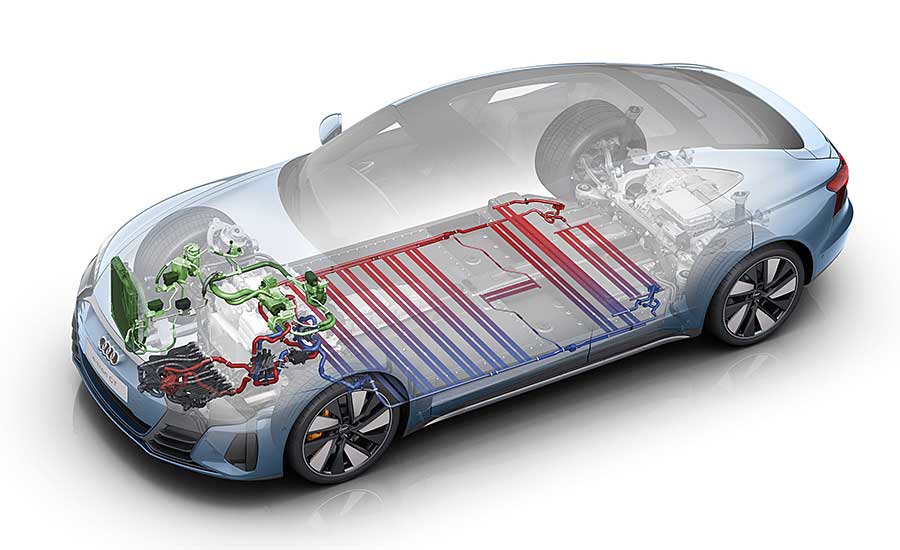

1. Advanced Thermal Insulation Materials: Thermal management is a vital aspect of electric vehicles, as batteries and power electronics generate significant heat. To prevent overheating, electric vehicle manufacturers are turning to high-performance insulation materials that can maintain thermal stability. Recent developments have led to the creation of innovative, lightweight, and high-temperature-resistant materials such as aerogels and advanced foams. These materials offer excellent thermal insulation properties, allowing the vehicle to operate more efficiently and extend the lifespan of its battery.

2. Electric Insulation for High-Voltage Components: Electric vehicles feature high-voltage electrical systems, which necessitate specialized insulation solutions to prevent electrical breakdowns. Manufacturers are now focusing on insulating materials capable of withstanding high voltages while maintaining flexibility and reliability. For instance, advancements in cross-linked polyethylene (XLPE) and silicone-based materials have made insulation more efficient in electric drivetrains and battery systems. These materials ensure that the electrical components of EVs remain safe and reliable under harsh conditions.

3. Noise, Vibration, and Harshness (NVH) Insulation: As electric vehicles become more mainstream, the demand for a quieter, smoother, and more comfortable driving experience has increased. Manufacturers have made notable progress in developing NVH insulation technologies to reduce cabin noise and improve comfort. Lightweight materials such as acoustic foams and sound-damping composites are being integrated into vehicle cabins to minimize the noise generated by electric motors and other vehicle components.

4. Biodegradable and Sustainable Insulation Solutions: With the growing demand for eco-friendly materials in the automotive industry, EV insulation manufacturers are exploring sustainable and biodegradable options. Researchers are working on developing plant-based insulations and recyclable polymers to reduce the environmental impact of the automotive sector. These materials provide effective insulation without compromising performance and contribute to the overall sustainability of electric vehicles.

5. Insulating Materials for EV Charging Infrastructure: As the adoption of electric vehicles grows, so does the need for a comprehensive charging infrastructure. Recent developments in insulation are also addressing the needs of EV charging stations. Insulating materials are being used to improve the durability and efficiency of charging cables, connectors, and stations, ensuring safe and efficient charging for electric vehicles. High-performance insulation is critical to protect against the heat generated during charging, as well as to prevent wear and tear on the equipment.

Challenges in the Electric Vehicle Insulation Market

While the electric vehicle insulation market has made substantial progress, several challenges remain. One of the main challenges is the high cost of advanced insulation materials, which can increase the overall manufacturing costs of EVs. However, as the market expands and demand increases, the cost of these materials is expected to decrease over time.

Another challenge is the need for a wide variety of insulation materials that can cater to the diverse needs of electric vehicles, including temperature control, safety, and acoustic insulation. As manufacturers seek to improve the efficiency of their vehicles, balancing cost, performance, and environmental concerns remains a key consideration.

Future Trends and Market Outlook

The electric vehicle insulation market is poised for continued growth in the coming years. As more automakers enter the EV market and as demand for electric vehicles surges globally, the need for advanced insulation materials will grow. Companies are investing in research and development to create innovative materials that provide improved thermal, electrical, and acoustic insulation.

Moreover, collaboration between automakers, material manufacturers, and technology providers will be essential to address the evolving demands of the electric vehicle industry. Governments are also expected to play a role in driving the development of sustainable insulation materials by offering incentives for environmentally friendly innovations.

In conclusion, the electric vehicle insulation market is undergoing significant transformations, with advancements in material science, manufacturing processes, and industry standards driving improvements in the performance, safety, and comfort of electric vehicles. These developments not only enhance the driving experience but also contribute to the wider goal of reducing the automotive industry's environmental impact. As demand for electric vehicles continues to rise, the insulation market will remain a key component in the success and sustainability of the EV sector.