The Li-Ion battery electrode coating market is undergoing significant advancements, driven by the growing demand for electric vehicles (EVs), renewable energy storage systems, and portable electronics. As the global emphasis shifts toward clean energy solutions and sustainability, the need for efficient, durable, and cost-effective battery technologies has never been greater. The electrode coating process, a crucial component of lithium-ion (Li-ion) batteries, plays a pivotal role in enhancing their performance, safety, and longevity.

Pioneering ideas in this market are primarily focused on improving the materials, techniques, and overall efficiency of electrode coatings. Traditionally, the coatings are made of materials such as graphite, lithium cobalt oxide, and lithium iron phosphate. However, there has been a surge in research to develop new coating materials that can increase energy density, charge/discharge rates, and thermal stability.

One such innovation is the use of nanostructured coatings, which promise enhanced surface area and conductivity, improving the overall battery efficiency. Nanomaterials like carbon nanotubes and graphene are gaining traction due to their exceptional electrical conductivity and mechanical properties. By integrating these materials into electrode coatings, manufacturers can create batteries with higher energy output and faster charging times, which are key to the future of electric mobility and large-scale energy storage.

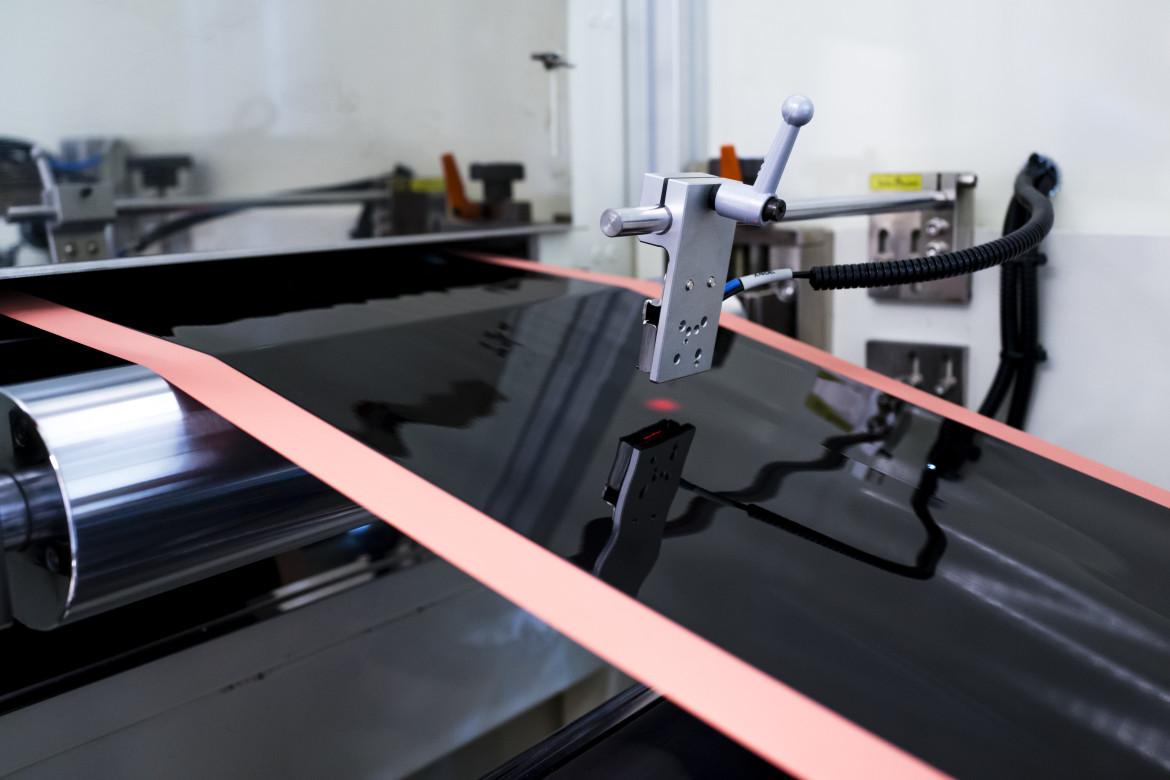

Another area of innovation lies in the automated coating processes. With the rapid growth of the EV industry, demand for scalable production methods is rising. Automation and precision in electrode coating applications allow for better control over thickness, uniformity, and material deposition, reducing manufacturing costs and ensuring more consistent performance in the final battery product.

Additionally, solid-state battery technology is gaining momentum as an alternative to traditional Li-ion batteries. By using solid-state electrolytes and novel electrode coating techniques, these batteries could offer improved safety and performance by reducing risks of thermal runaway and degradation, which are challenges with conventional Li-ion designs.

In conclusion, the Li-ion battery electrode coating market is ripe for innovative solutions. The evolution of advanced materials, manufacturing processes, and the integration of solid-state technologies will play a crucial role in shaping the future of energy storage and propulsion systems.