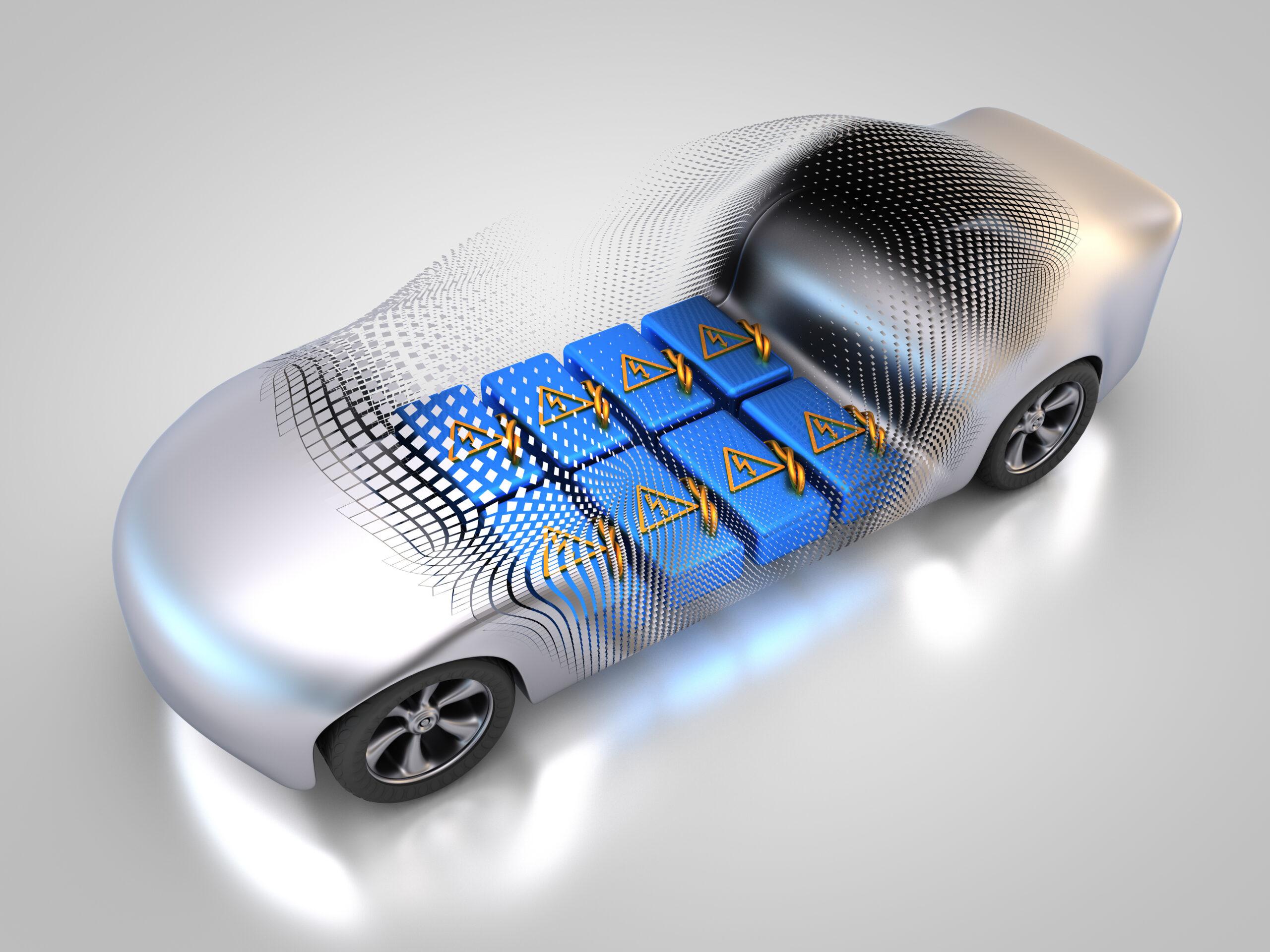

The electric vehicle battery adhesive market is poised for significant growth in the coming years as the global shift toward electric mobility continues to gain momentum. Over the next decade, the increasing adoption of electric vehicles (EVs), advancements in battery technology, and evolving regulatory landscapes will drive demand for high-performance adhesives designed to meet the specific needs of EV battery packs. This market's long-term outlook hinges on several critical factors that will shape the direction of innovation, growth, and market dynamics.

Increasing Global Adoption of EVs

- The continued rise in electric vehicle sales globally is the primary factor driving the long-term demand for electric vehicle battery adhesive market products. Governments worldwide are implementing stringent environmental regulations, with many setting ambitious targets for phasing out internal combustion engine vehicles in favor of electric alternatives. As EV adoption grows, the need for efficient, high-quality adhesives for battery systems will be a key enabler of this transition.

Advancements in Battery Technologies

- As electric vehicle batteries evolve, so does the demand for adhesives capable of withstanding higher temperatures, more complex designs, and advanced chemistries. The development of solid-state and lithium-sulfur batteries, for example, requires adhesives that can provide better thermal conductivity, flexibility, and stability over extended periods. These technological advancements will fuel innovation in the electric vehicle battery adhesive market, leading to specialized adhesives tailored for next-generation battery technologies.

Stringent Safety Regulations and Standards

- Safety concerns are paramount when it comes to electric vehicle batteries, particularly regarding the risk of thermal runaway, electrical short circuits, and structural integrity. In the long term, the electric vehicle battery adhesive market will see an increasing demand for adhesives that offer superior fire resistance, shock absorption, and impact resistance. Adhesive manufacturers will need to continue to develop products that meet or exceed regulatory standards for safety, particularly as governments impose stricter regulations on EV manufacturers.

Sustainability Trends in Manufacturing

- Sustainability is becoming a key consideration in all industries, including the EV sector. Consumers and manufacturers alike are pushing for environmentally friendly solutions that minimize waste and reduce carbon footprints. The electric vehicle battery adhesive market will increasingly focus on producing adhesives that are more sustainable, both in terms of raw materials and the manufacturing process. Companies will invest in developing eco-friendly adhesives that do not compromise on performance, durability, or safety, aligning with the overall sustainability goals of the automotive industry.

Shift Towards Lightweight and Compact EV Designs

- One of the primary trends driving innovation in the electric vehicle battery adhesive market is the industry's focus on creating lightweight, compact battery systems. Reducing the weight of batteries not only enhances vehicle efficiency and range but also addresses consumer concerns over battery size and cost. Adhesives provide a solution for bonding and securing components without adding significant weight, making them a vital part of the lightweight design strategy. As automakers continue to prioritize lightweight EVs, the demand for adhesives capable of replacing heavier mechanical fasteners will increase.

Customization and Specialized Adhesive Solutions

- The electric vehicle battery adhesive market is witnessing a shift toward more customized solutions as automakers seek adhesives tailored to specific battery designs and applications. Adhesive manufacturers will be required to work closely with automakers and battery manufacturers to create formulations that meet the unique challenges of each new battery technology. This trend toward specialization will result in a more diverse range of adhesive products, each designed to address specific needs such as high-performance bonding, thermal management, and electrical insulation.

Long-Term Market Growth in Emerging Regions

- While the electric vehicle battery adhesive market is currently dominated by regions such as North America, Europe, and Asia-Pacific, emerging economies in Latin America, Africa, and Southeast Asia will see increasing demand for EVs and related components in the long run. As infrastructure for EVs develops and the cost of electric vehicles becomes more competitive with traditional vehicles, these regions will become key markets for battery adhesives. The increasing presence of global automotive manufacturers in these areas will drive the need for localized adhesive solutions.

Collaborations and Strategic Partnerships

- Over the long term, strategic collaborations between automotive OEMs, battery manufacturers, and adhesive suppliers will become more common. These partnerships will enable the development of specialized adhesive solutions that cater to the evolving needs of electric vehicle battery systems. By working together, these stakeholders can create products that improve battery efficiency, enhance safety, and reduce costs, ultimately benefiting the entire EV value chain.

Innovation in Adhesive Materials and Manufacturing Techniques

- As the demand for higher-performance adhesives grows, manufacturers in the electric vehicle battery adhesive market will increasingly invest in research and development to explore new materials and manufacturing techniques. Innovations in nanotechnology, advanced polymers, and bio-based adhesives will open up new possibilities for improving battery performance, safety, and sustainability. These advancements will play a crucial role in meeting the long-term needs of the electric vehicle industry.

Challenges in Cost Management

- While the long-term outlook for the electric vehicle battery adhesive market is positive, the cost of raw materials and manufacturing processes presents a significant challenge. The development of high-performance adhesives often involves expensive materials and complex production processes, which can increase the overall cost of EV production. Over time, as the market matures and economies of scale are achieved, these costs are expected to decrease, making adhesives more affordable for automakers and consumers alike.