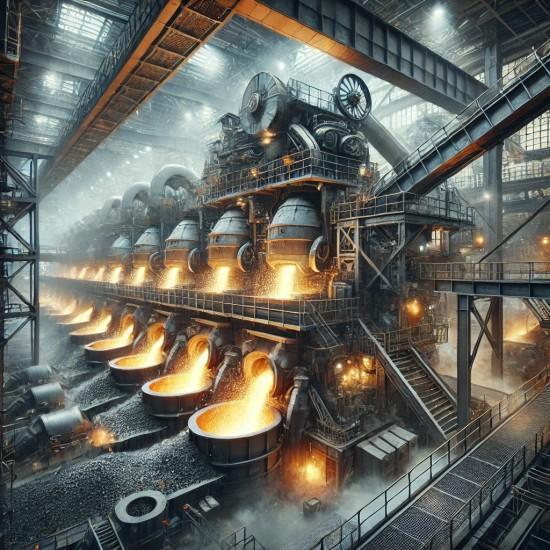

The Steel Slag Equipment Market is witnessing significant expansion as industries worldwide seek sustainable solutions for slag processing and recycling. As steel production continues to grow, the need for advanced equipment to handle and repurpose steel slag is increasing. Technological advancements in crushing, grinding, and metal separation have enhanced efficiency, making slag recycling a more viable and profitable industry. Growing environmental concerns and government regulations promoting circular economy initiatives are further driving market growth. As industries focus on resource optimization, the demand for innovative steel slag equipment is expected to surge.

Growing Demand for Sustainable Solutions

Sustainability has become a primary focus in the steel sector, leading to increased investments in slag recycling equipment. Governments and regulatory bodies are encouraging industries to minimize waste and adopt environmentally friendly disposal methods. Steel slag, once considered an industrial byproduct, is now being used in construction, roadways, and cement production, creating a lucrative market for equipment manufacturers. The shift towards sustainable infrastructure and eco-friendly materials has significantly boosted the demand for slag processing equipment.

Technological Innovations Enhancing Efficiency

Advancements in slag processing technology have revolutionized the industry, making steel slag equipment more efficient and cost-effective. Modern crushers, separators, and screening systems are designed to maximize metal recovery while minimizing waste. Automated sorting systems, AI-driven analytics, and advanced material handling solutions have improved productivity, reducing manual intervention. These innovations are not only enhancing efficiency but also ensuring compliance with stringent environmental regulations, positioning manufacturers at the forefront of the industry.

Expanding Applications in Various Sectors

Steel slag is increasingly being utilized in diverse applications, driving the need for specialized equipment. The construction industry benefits from its use in concrete and asphalt production, offering a sustainable alternative to natural aggregates. The road-building sector is leveraging steel slag for durable and high-performance pavements. Additionally, the cement industry incorporates slag as a supplementary material, reducing CO₂ emissions and improving product quality. As new applications emerge, demand for specialized processing equipment is expected to grow.

Government Policies and Market Incentives

Regulatory policies and incentives promoting sustainable waste management are positively influencing the steel slag equipment market. Governments across regions are implementing stringent guidelines for industrial waste disposal, compelling steel producers to invest in efficient slag processing solutions. Subsidies and tax benefits for companies adopting eco-friendly technologies have encouraged market expansion. Additionally, international organizations are advocating for circular economy principles, further boosting investments in slag recycling technologies.

Challenges in the Steel Slag Equipment Market

Despite its growth potential, the industry faces several challenges that could impact market expansion. High initial investment costs for advanced equipment and processing plants pose financial constraints for small and mid-sized manufacturers. Additionally, variations in slag composition make standardization a challenge, requiring customized solutions for different types of slag. Market players must also navigate fluctuating raw material prices and regulatory complexities, which can affect profitability. Addressing these challenges through innovation and strategic partnerships will be crucial for sustained market growth.

Regional Market Trends and Opportunities

The global steel slag equipment market exhibits significant regional variations based on industrial activity and regulatory frameworks. Asia-Pacific, led by China and India, dominates the market due to rapid industrialization and expanding steel production. North America and Europe are witnessing steady growth, driven by environmental regulations and increasing adoption of sustainable practices. Emerging markets in Latin America and Africa present untapped opportunities, with governments emphasizing industrial development and infrastructure expansion. Understanding regional dynamics will be key to capitalizing on market potential.

Competitive Landscape and Future Outlook

The competitive landscape of the steel slag equipment market is characterized by the presence of key players focusing on technological advancements and strategic collaborations. Companies are investing in research and development to introduce innovative equipment with higher efficiency and lower environmental impact. Mergers, acquisitions, and partnerships are common strategies adopted to strengthen market presence. With increasing awareness of resource efficiency and circular economy principles, the market is expected to witness continuous growth in the coming years.

Conclusion

The steel slag equipment market is poised for substantial growth, driven by sustainability initiatives, technological advancements, and expanding applications. As industries seek efficient slag processing solutions, manufacturers have significant opportunities to innovate and expand their market presence. With supportive government policies and rising demand for eco-friendly materials, the industry is set to play a crucial role in global waste management and resource optimization.