Frac Sand Market Innovations Shaping the Future of Oil and Gas Extraction

The frac sand market has undergone significant changes over recent years, driven by advancements in technology and growing demand from the energy sector. As the use of hydraulic fracturing continues to expand, innovations in frac sand production, transportation, and application have emerged to optimize efficiency, reduce environmental impact, and lower costs. These innovations are expected to have a substantial impact on the market in 2025 and beyond.

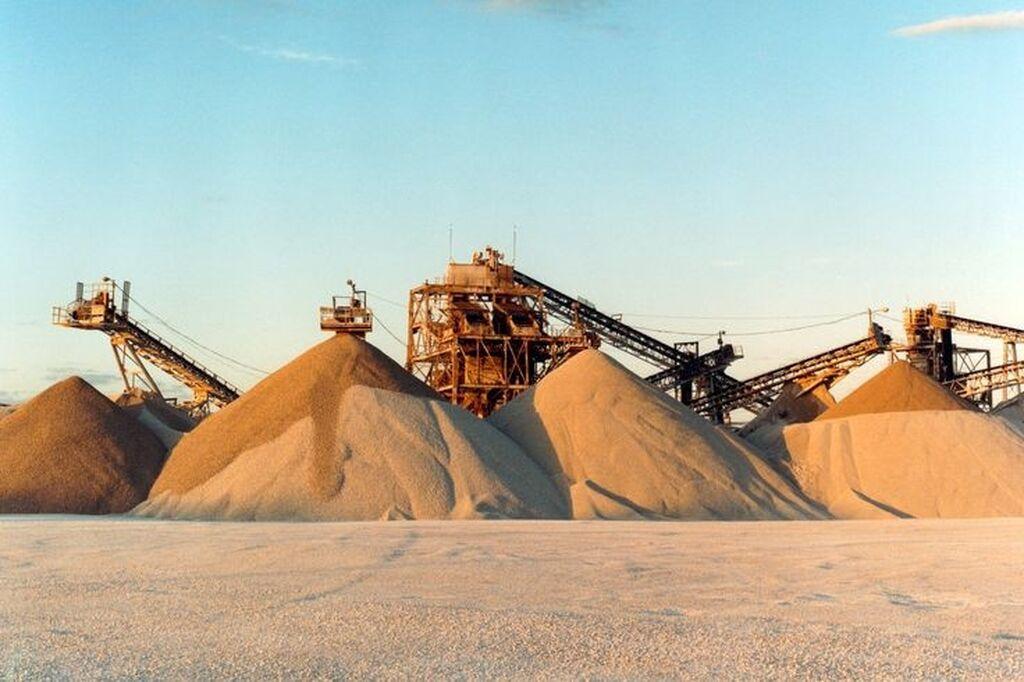

1. Technological Advancements in Frac Sand Production

- Enhanced mining techniques, such as automated extraction, are improving production efficiency and reducing costs.

- High-tech sorting methods are being implemented to ensure that only high-quality frac sand is used, reducing waste and improving performance.

- Artificial intelligence (AI) and machine learning (ML) are now being applied to optimize frac sand mining operations, providing more precise data for decision-making and ensuring better resource management.

2. In-Basin Sand Production

- In response to transportation challenges, more operators are turning to in-basin frac sand production.

- This reduces the cost and logistical challenges associated with shipping sand from distant mines to fracking sites.

- In-basin sand production has been a game-changer, especially in the Permian Basin, where local sand production has dramatically reduced transportation costs and time.

- The trend is expected to grow, with more basins likely to invest in local sand mines by 2025, leading to improved cost-effectiveness for operators.

3. Eco-Friendly and Sustainable Frac Sand Practices

- Environmental concerns are pushing the frac sand market toward more sustainable practices.

- New mining technologies are being developed to minimize dust emissions, making frac sand extraction less harmful to the environment.

- Some frac sand suppliers are adopting water recycling techniques to reduce water usage, particularly in regions with limited water resources.

- The push for sustainability is expected to increase as more regulations regarding environmental practices are implemented in 2025 and beyond.

4. Use of Resin-Coated Frac Sand

- Resin-coated frac sand is gaining popularity as it provides better conductivity and is more durable than traditional frac sand.

- This type of sand is coated with a resin that binds the grains together, offering superior crush resistance, which is essential for maintaining high productivity in wells.

- Although resin-coated sand is more expensive than traditional frac sand, its ability to improve well performance is driving increased adoption.

- By 2025, the market for resin-coated frac sand is projected to expand significantly due to its superior performance in high-pressure wells.

5. Automation and Digitalization in Frac Sand Logistics

- Digital technologies are revolutionizing the logistics of frac sand delivery, helping operators optimize sand distribution across various fracking sites.

- Automated trucks and conveyor systems are now used to transport frac sand, reducing the dependence on human labor and improving safety.

- Companies are also adopting real-time tracking systems that allow them to monitor sand usage and ensure efficient supply chains.

- This digital transformation is expected to grow through 2025, with innovations in IoT (Internet of Things) and machine-to-machine communication further enhancing the logistics of frac sand delivery.

6. Advanced Fracking Techniques Increasing Sand Demand

- Innovations in hydraulic fracturing techniques, such as extended-reach horizontal drilling and multi-stage fracking, require more sand to keep the fractures open.

- This shift to more intensive fracking processes is increasing the demand for frac sand as operators seek more efficient methods to enhance oil and gas production.

- The growing demand for unconventional resources will continue to drive the need for high-quality frac sand in the coming years.

7. Lightweight Frac Sand Alternatives

- Research into lightweight alternatives to traditional frac sand is underway, with the aim of reducing transportation costs while maintaining high efficiency.

- These alternatives are designed to perform similarly to traditional frac sand but weigh less, which reduces the amount of energy needed for transportation.

- Lightweight frac sand is seen as a potential solution to transportation bottlenecks and is expected to enter the market by 2025 as a viable alternative.

8. Frac Sand Recycling

- The recycling of frac sand has become a significant trend as operators aim to reduce waste and lower costs.

- After a well has been completed, the used frac sand can be cleaned and reused for subsequent fracking operations.

- This practice not only saves money but also reduces the environmental impact of frac sand mining, as fewer new resources are needed.

- By 2025, frac sand recycling technologies are expected to improve, further advancing the sustainability of the industry.

9. Integration of Proppant-Free Hydraulic Fracturing

- In recent years, some companies have explored the use of proppant-free hydraulic fracturing methods, which eliminate the need for traditional frac sand.

- These methods rely on creating fractures that do not require proppants to keep them open, significantly reducing the amount of sand needed.

- Although still in the experimental stage, these innovations may disrupt the frac sand market in the future, potentially leading to decreased demand for traditional frac sand in certain fracking operations.

10. Strategic Partnerships and Mergers in the Market

- Strategic collaborations between frac sand producers, logistics companies, and oil and gas operators are becoming more common.

- These partnerships allow for better coordination, lower transportation costs, and improved sand delivery efficiency.

- The trend of mergers and acquisitions is expected to continue as companies look to consolidate resources and strengthen their market positions by 2025.