Human-Centered Design Approaches in Ultrasonic Plastic Welding Machines

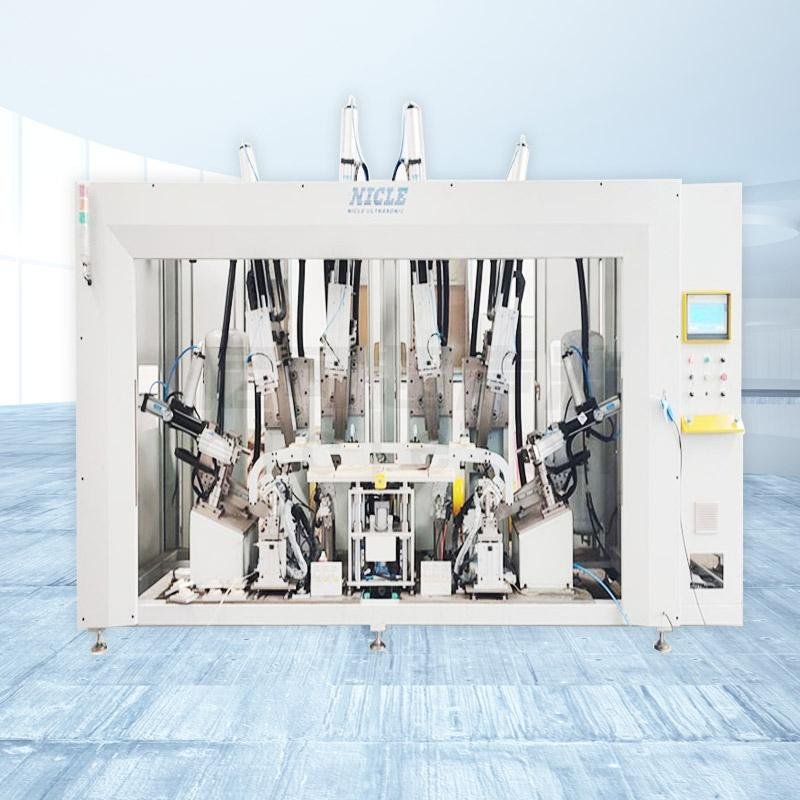

Human-centred design is becoming a defining factor in how industrial equipment is built and used. In ultrasonic plastic welding machines, this shift matters because operators, engineers, and production managers all interact with these systems daily. A poorly designed interface or unsafe workflow can lead to reduced efficiency, higher training costs, and even injury. A well-designed machine, on the other hand, aligns with human needs while still achieving technical performance.

This article explores how human-centred design principles are applied in ultrasonic plastic welding machines. It looks at operator safety, usability, ergonomics, digital integration, and sustainability—showing how manufacturers are building machines that meet both industrial and human requirements.

What is Human-Centred Design?

Human-centred design (HCD) is a framework that prioritises the needs, skills, and limitations of people who use a product. In industrial machinery, HCD translates into:

-

Intuitive controls that minimise errors.

-

Safe interaction points that reduce risks.

-

Feedback systems that give operators confidence.

-

Designs that consider fatigue, accessibility, and long-term usability.

For ultrasonic welding machines, which are used across automotive, medical, and electronics sectors, adopting HCD ensures that machines are not only technically sound but also practical and safe for real-world users.

Ergonomics and Operator Safety

Ultrasonic plastic welding involves high-frequency vibrations and pressure to bond thermoplastic components. This process requires precision and safe handling. Human-centred approaches improve operator safety in several ways:

-

Ergonomic layouts: Machines are increasingly designed with adjustable working heights and easy-to-reach controls, reducing strain on operators.

-

Noise reduction: Ultrasonic welding can generate high-pitched sounds. Modern systems integrate acoustic enclosures and sound-dampening designs to protect hearing.

-

Guarding and sensors: Safety barriers and light curtains prevent accidental access to dangerous moving parts.

By embedding safety features in the design, manufacturers reduce downtime and liability while protecting users.

Usability and Intuitive Interfaces

Earlier generations of welding machines often relied on complex control panels requiring specialist training. Human-centred design has shifted towards interfaces that are easier to understand:

-

Touchscreen controls: Operators can access pre-set welding parameters with minimal steps.

-

Visual feedback: Real-time graphs and alerts make it easier to monitor welding quality.

-

Multi-language support: Interfaces often provide language options, reducing misinterpretation in global facilities.

These usability improvements reduce operator error, shorten training times, and improve productivity.

Digital Integration and Data-Driven Design

Industry 4.0 has pushed welding machines into the digital age. Human-centred design here means making digital tools work for operators rather than overwhelm them:

-

Predictive maintenance: Machines now provide alerts before breakdowns occur, allowing operators to schedule servicing.

-

Data visualisation: Weld quality data is displayed in simplified dashboards, making it easier for production teams to identify issues.

-

Connectivity: Machines connect to factory networks, allowing managers to track performance remotely.

Digitalisation is valuable only when information is actionable. Human-centred systems filter out unnecessary complexity and highlight what the user actually needs.

Training and Accessibility

Accessibility is a growing priority in industrial equipment. Human-centred ultrasonic welding machines now include:

-

Guided training modes: Interactive tutorials embedded in the control system help new operators learn faster.

-

Modular systems: Components can be swapped without specialised tools, reducing dependence on expert technicians.

-

Remote assistance: Some machines allow service teams to log in remotely to assist operators in real time.

These features not only improve accessibility but also reduce training costs for employers.

Sustainability and Human Impact

Human-centred design also extends to sustainability, recognising that environmental impact affects human well-being:

-

Energy-efficient transducers: Machines are built to use less electricity while delivering precise welds.

-

Material optimisation: Systems provide feedback on weld strength, helping reduce waste from failed parts.

-

Compact footprints: Smaller, modular designs save floor space and resources in production environments.

By focusing on long-term sustainability, these machines contribute to safer, cleaner, and more efficient workplaces.

Key Human-Centred Design Features in Ultrasonic Plastic Welding Machines

| Feature | Human-Centred Benefit |

|---|---|

| Ergonomic workstations | Reduces strain and fatigue |

| Touchscreen controls | Simplifies operation |

| Acoustic enclosures | Protects operator hearing |

| Predictive maintenance alerts | Minimises unplanned downtime |

| Guided tutorials | Lowers training requirements |

| Data dashboards | Clear insights for decision-making |

Challenges in Human-Centred Design

While advances are clear, challenges remain:

-

Cost pressures: Adding ergonomic and digital features can raise initial machine prices.

-

Complexity vs. simplicity: Balancing advanced capabilities with a clean, intuitive interface is not easy.

-

Standardisation: Operators often work across different brands of machines, so inconsistent design language can lead to errors.

These challenges highlight why continuous improvement and user feedback are essential in design.

The Future of Human-Centred Ultrasonic Welding

Looking ahead, several trends are set to strengthen human-centred design:

-

AI-powered weld monitoring: Automated systems that adjust parameters in real time.

-

Voice-controlled interfaces: Reducing reliance on manual controls.

-

Collaborative robots (cobots): Assisting operators with repetitive welding tasks.

-

Enhanced accessibility: Machines designed with universal usability, accommodating a wider range of physical abilities.

These developments will further align ultrasonic welding machines with human needs, making them smarter, safer, and easier to use.

Conclusion

Human-centred design in ultrasonic plastic welding machines is no longer optional—it is expected. By focusing on ergonomics, intuitive controls, safety, and sustainability, manufacturers are creating machines that are technically advanced yet human-friendly. For operators, this means safer, simpler, and more productive work. For businesses, it translates into reduced errors, lower training costs, and stronger long-term value.

As industries continue to demand precision and efficiency, those who integrate human-centred principles into ultrasonic welding equipment will be best placed to lead the market.