Aircraft Machine Tools Market: Precision at the Core of Aviation Manufacturing

Aircraft machine tools are advanced equipment used in the manufacturing and machining of aerospace components such as engine parts, fuselage structures, wings, and landing gear. These tools include CNC machining centers, milling machines, lathes, grinders, and drilling machines that ensure precision, efficiency, and repeatability. According to Stratview Research, the aircraft machine tools market is experiencing steady growth, supported by the rising demand for next-generation aircraft and increasing production rates by leading OEMs such as Airbus and Boeing.

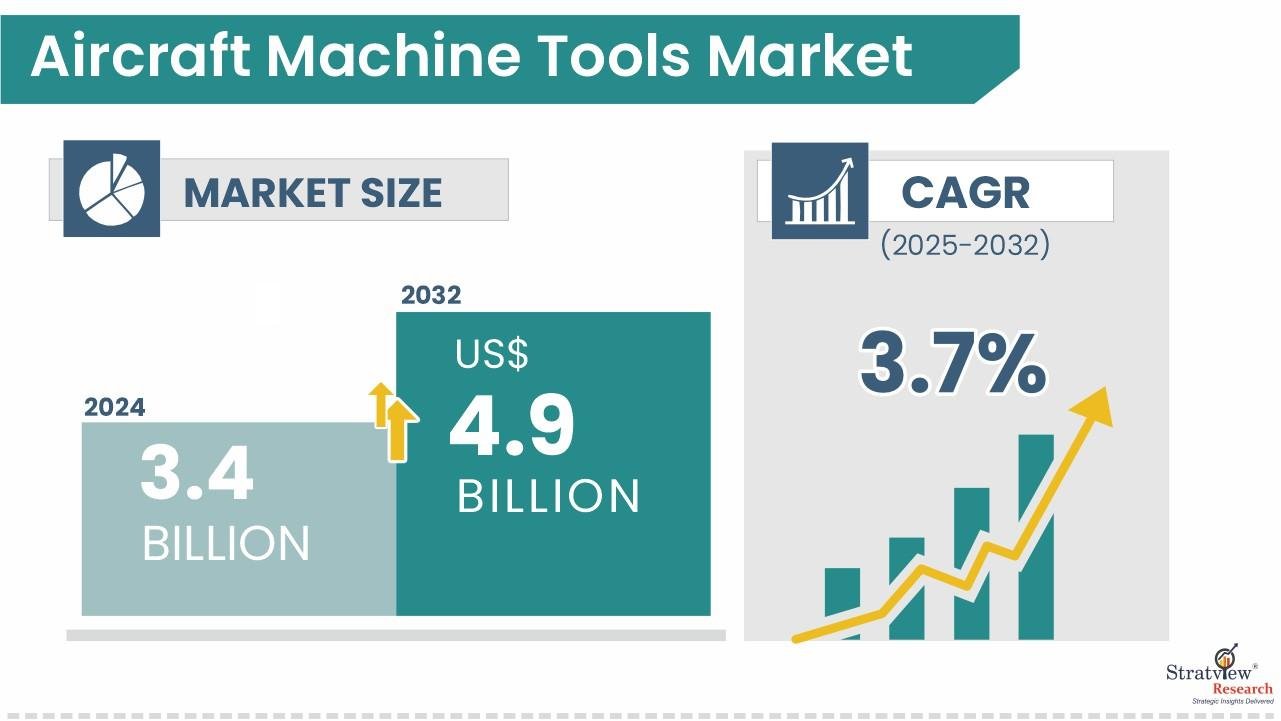

The aircraft machine tools market was USD 3.5 billion in 2024 and is likely to grow at a CAGR of 3.7% during 2025-2032 to reach USD 4.9 billion in 2032.

Download the sample report here:

https://www.stratviewresearch.com/Request-Sample/3584/aerospace-machine-tools-market.html#form

Key Market Drivers

- Rising Aircraft Production: The surge in commercial air travel is pushing OEMs to expand production, driving demand for high-performance machine tools.

- Military Modernization: Advanced fighter jet and helicopter programs require complex machining solutions for titanium, composites, and superalloys.

- Material Shifts: Growing use of composites, titanium, and high-strength alloys demands specialized machining systems.

- MRO and Aftermarket Growth: Engine overhaul and component repair are fueling demand for flexible and precise machining equipment.

- Automation & Efficiency: Increasing pressure to reduce cycle times and production costs enhances adoption of CNC and automated systems.

Emerging Trends

- Multi-axis CNC Machining: Adoption of 5-axis and 7-axis machines for complex geometries.

- Hybrid Manufacturing: Integration of additive manufacturing with machining for faster prototyping.

- Digital Twins & Simulation: Use of virtual models for predictive machining and tool optimization.

- Lightweight Material Machining: Specialized tools for composite cutting and titanium drilling.

- Sustainable Manufacturing: Machine tools optimized for energy efficiency and reduced material waste.

Applications

- Engines: Turbine blades, casings, and high-temperature components.

- Airframes: Machining of fuselage sections, wings, and empennage structures.

- Landing Gear: Precision tools for machining heavy-duty structural components.

- Composite Components: Drilling and trimming of carbon fiber-reinforced polymer (CFRP) structures.

- MRO Services: Repair and remanufacturing of worn aerospace parts.

Conclusion

The aircraft machine tools market is central to the industry’s ability to meet rising production targets and new design challenges. With OEM backlogs stretching years ahead and increasing demand for lightweight, high-strength components, investments in precision machining, automation, and hybrid technologies are accelerating. Suppliers that deliver high-performance, flexible, and sustainable solutions will continue to capture market growth.