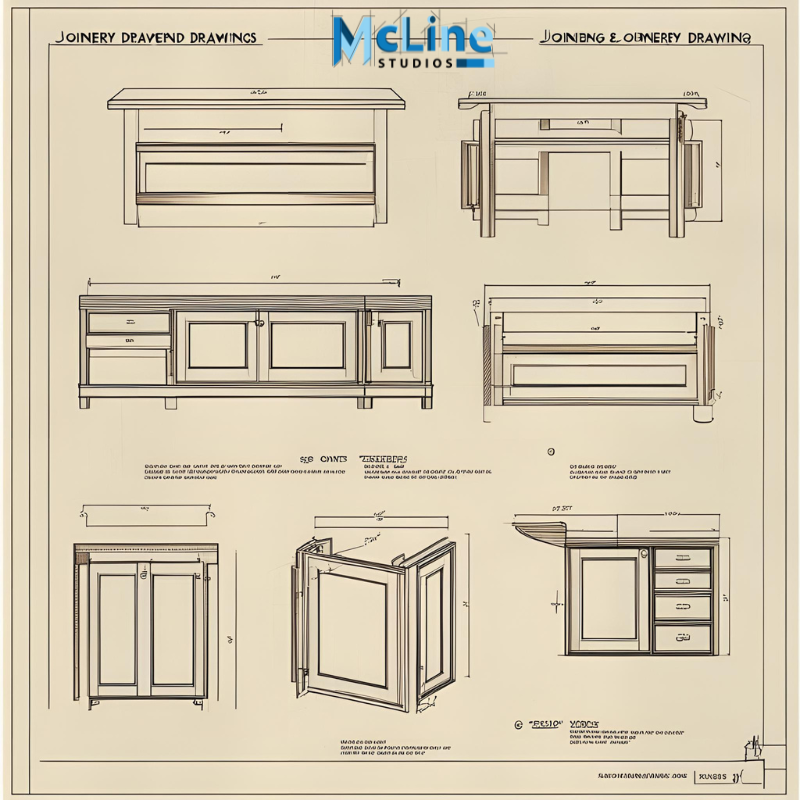

In the evolving landscape of architectural and interior design, precision and efficiency are more critical than ever. Traditional joinery drawings have long been the backbone of woodworking and millwork projects, ensuring accurate fabrication and seamless installations. However, as construction and manufacturing technologies advance, integrating Artificial Intelligence (AI) and Building Information Modeling (BIM) is reshaping how joinery drawings are created, analyzed, and utilized.

AI-driven automation streamlines drafting processes, reducing manual errors and optimizing design iterations, while BIM enhances collaboration by providing a digital twin of the entire project. Together, these technologies enable designers, manufacturers, and contractors to work with greater accuracy, efficiency, and cost-effectiveness.

This article explores how AI and BIM are revolutionizing joinery drawings, making them more intelligent, adaptive, and integral to modern construction workflows.

Traditional Joinery Drawings: Challenges and Limitations

Traditional joinery drawings have been used for centuries to guide woodworkers in crafting precise joints for furniture, cabinetry, and architectural woodwork. While they hold historical value, they also come with several challenges and limitations.

One major challenge is accuracy. Hand-drawn joinery plans rely on the skill of the drafter. Even a small mistake in measurements can lead to improper fits, requiring adjustments during assembly. This slows down the process and increases material waste.

Another limitation is modifications and revisions. Unlike digital drawings, making changes in traditional hand-drawn plans is time-consuming. If an error is found or a design update is needed, the entire drawing might have to be redone. This is especially difficult in large-scale projects where multiple revisions are common.

Communication issues also arise with traditional joinery drawings. Since they are manually drafted, there may be inconsistencies in symbols or annotations. Workers might misinterpret dimensions or joinery details, leading to costly errors in production.

Also, storage and sharing of these drawings can be a problem. Paper drawings are prone to wear and tear, loss, or damage over time. Unlike digital files, they cannot be easily duplicated or shared with teams in different locations.

Finally, traditional methods lack integration with modern machinery. CNC machines and automated cutting tools require digital formats for precision manufacturing. Converting hand-drawn plans into digital versions adds an extra step, increasing project timelines.

Despite their craftsmanship, traditional joinery drawings are slowly being replaced by CAD software, which offers greater accuracy, efficiency, and flexibility in woodworking projects.

The Role of BIM in Joinery Drawings

Building Information Modeling (BIM) has transformed the way joinery drawings are created and used in construction projects. Joinery, which includes custom-built furniture, cabinets, doors, and other wooden elements, requires precise planning and detailing. BIM helps improve accuracy, efficiency, and collaboration in this process.

One of the biggest benefits of BIM in joinery drawings is better visualization. With 3D modeling, designers, architects, and clients can see how the joinery elements will look in the final space. This reduces errors and ensures that the design meets expectations before production begins.

BIM also allows for precise measurements and detailing. Unlike traditional 2D drawings, BIM provides highly accurate dimensions, material specifications, and installation details. This helps manufacturers produce joinery pieces with exact precision, reducing waste and rework.

Another advantage is improved coordination. In construction projects, multiple teams work together, including architects, engineers, and joinery specialists. BIM allows them to share real-time updates, ensuring that any design changes are instantly communicated to everyone involved. This avoids clashes or misalignment during installation.

Also, BIM improves cost estimation and material management. Since BIM models contain detailed information about materials and quantities, it helps in planning budgets and reducing unnecessary costs.

Overall, BIM plays a crucial role in joinery drawings by enhancing accuracy, improving collaboration, and reducing mistakes. As technology advances, the use of BIM in joinery will continue to grow, making the design and manufacturing process smoother and more efficient.

How AI is Revolutionizing Joinery Drawings

Artificial Intelligence (AI) is transforming the way joinery drawings are created and used in woodworking and construction. Traditionally, joinery drawings required skilled drafters to manually design each detail. This process was time-consuming and had a higher chance of human error. However, AI-powered tools are making this process faster, more accurate, and highly efficient.

One of the biggest advantages of AI in joinery drawings is automation. AI can quickly generate accurate shop drawings by analyzing project requirements. It can suggest the best joinery techniques based on material type, dimensions, and load-bearing capacity. This helps designers and manufacturers save time and reduce waste.

AI also improves precision. It can detect design flaws before production, minimizing errors and costly rework. With AI-driven software, changes can be made easily, ensuring that all drawings remain up to date. Additionally, AI-powered tools can integrate with CNC machines, allowing for seamless and error-free manufacturing.

Another major benefit is AI’s ability to optimize material usage. AI algorithms can calculate the most efficient way to cut and assemble materials, reducing waste and costs.

AI is also making collaboration easier. Cloud-based AI tools allow architects, designers, and manufacturers to work on the same drawings in real-time, improving communication and project efficiency.

As AI technology continues to evolve, joinery drawings will become even more precise, automated, and cost-effective. This revolution is helping the woodworking and construction industries achieve better results with less effort.

AI and BIM Integration: The Future of Smart Joinery Drawings

The construction and woodworking industries are rapidly evolving with the help of technology. One of the biggest advancements in recent years is the integration of Artificial Intelligence (AI) and Building Information Modeling (BIM) in joinery drawings. This combination is making design, planning, and production smarter, faster, and more accurate than ever before.

How AI Helps in Joinery Drawings

AI-powered software can quickly analyze complex joinery designs and detect errors before production begins. It can suggest improvements, optimize materials, and even predict potential issues in installation. This reduces costly mistakes and speeds up the overall workflow.

BIM’s Role in Smart Joinery

BIM creates a 3D digital model that includes every detail of a joinery project. This helps designers, architects, and manufacturers work together efficiently. With BIM, changes in design are updated in real-time, ensuring that everyone is on the same page. It also allows for better cost estimation and material planning.

The Future of Smart Joinery Drawings

When AI and BIM work together, joinery drawings become more than just blueprints—they become intelligent models that guide the entire process from design to installation. This leads to higher precision, less waste, and smoother project execution.

As technology continues to improve, AI and BIM will make joinery drafting even more efficient and sustainable, shaping the future of smart construction and woodworking.

The Final Note

The integration of AI and BIM in joinery drawings is revolutionizing the woodworking and construction industries. By combining AI-driven automation with BIM’s digital modeling capabilities, designers, manufacturers, and contractors can work more efficiently, reduce errors, and optimize material usage.

AI enhances precision, speeds up drafting processes, and minimizes waste, while BIM fosters collaboration, ensures real-time updates, and improves project coordination. Together, these technologies are transforming traditional joinery drawings into intelligent, adaptive, and highly efficient tools.

As AI and BIM continue to evolve, they will further streamline the design-to-production workflow, making smart joinery drawings the new standard in modern construction and woodworking.