The composite roller market has seen significant growth in recent years, driven by advancements in materials science and increased demand for more durable and efficient components across various industries. These rollers, made from composite materials such as carbon fiber, glass fiber, and aramid fibers, offer superior performance compared to traditional metal or rubber rollers. This article explores the key dynamics shaping the composite roller market, including growth drivers, challenges, and the future outlook.

1. Market Drivers

1.1 Growing Demand in Industrial Applications

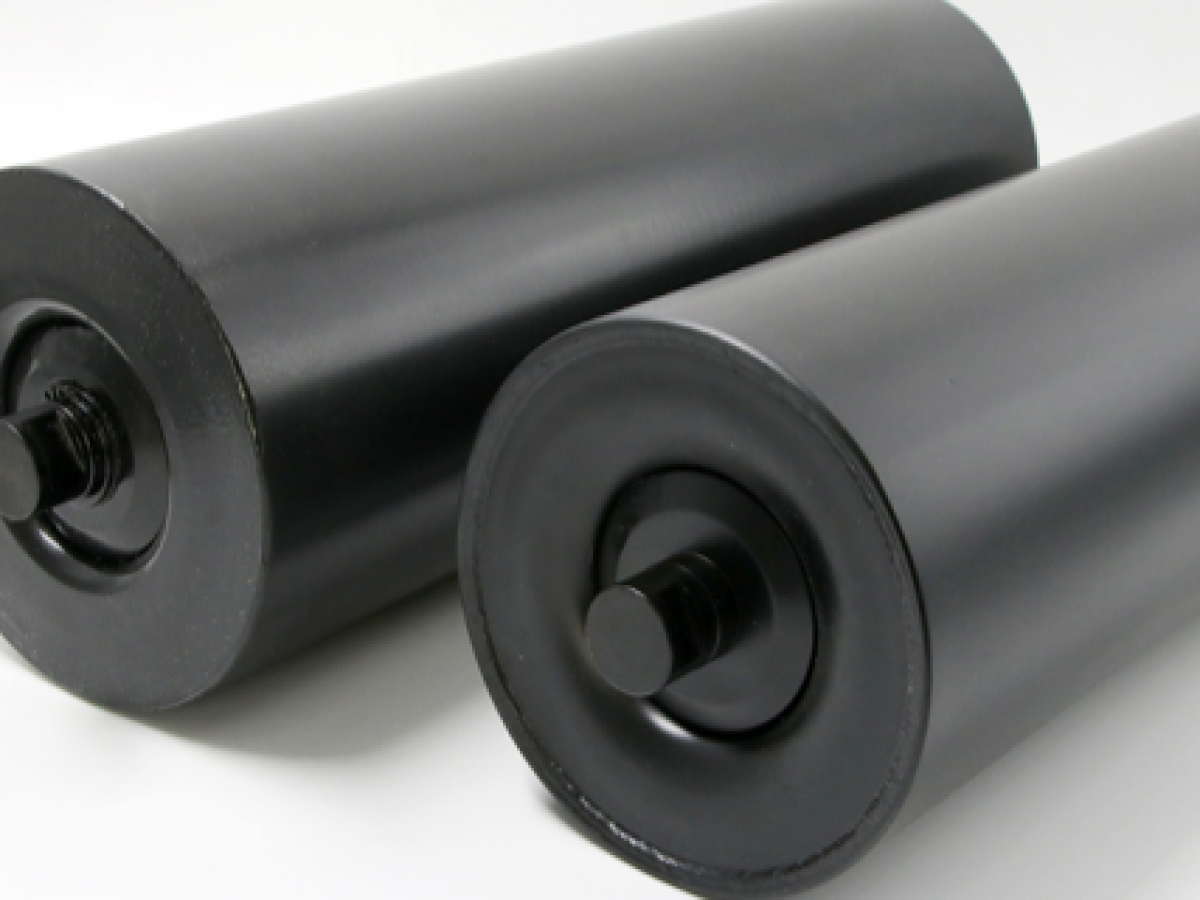

Composite rollers have found widespread applications in industries such as manufacturing, packaging, mining, and transportation due to their enhanced strength-to-weight ratio, corrosion resistance, and longer lifespan. In manufacturing, composite rollers are utilized in conveyor systems, helping to reduce downtime and maintenance costs. The increased adoption of automated systems, which require high-performance components, further fuels the demand for composite rollers.

1.2 Enhanced Durability and Performance

One of the primary reasons for the rise of composite rollers is their improved durability compared to conventional materials. Composites are more resistant to wear and tear, corrosion, and extreme temperatures, making them ideal for high-stress environments. In industries like mining and logistics, where equipment is subject to heavy loads and harsh conditions, composite rollers ensure operational continuity with fewer breakdowns and lower maintenance requirements.

1.3 Sustainability Trends

The increasing emphasis on sustainability and reducing carbon footprints is another driving force in the composite roller market. Composites, especially those made from recycled or eco-friendly fibers, offer a more sustainable alternative to traditional materials. Their lighter weight also contributes to energy efficiency by reducing fuel consumption in transport applications. As industries worldwide focus on adopting greener solutions, the demand for composite rollers is expected to rise, further bolstering market growth.

2. Market Challenges

2.1 High Initial Costs

One of the main challenges hindering the widespread adoption of composite rollers is their high initial cost. The manufacturing process for composite materials can be expensive, particularly when high-performance fibers like carbon or aramid are used. This price barrier can make it difficult for small and medium-sized enterprises (SMEs) to justify the switch from traditional materials, despite the long-term cost savings in maintenance and energy efficiency.

2.2 Technical Expertise and Manufacturing Limitations

The production of composite rollers requires specialized manufacturing techniques and technical expertise. Not all manufacturers have the necessary facilities or knowledge to produce high-quality composite rollers, limiting the scalability of their use in certain regions or industries. Additionally, ensuring consistency and reliability in the composite material properties is critical, as variations in fiber orientation, resin content, or curing process can affect the roller’s performance.

2.3 Competitive Substitutes

While composite rollers offer numerous advantages, they face competition from other materials such as polyurethane, steel, and aluminum, which are often more readily available and less expensive. In some applications, these traditional materials may still be perceived as more cost-effective, particularly in industries where performance demands are not as high. Overcoming this competition requires manufacturers to demonstrate the clear long-term benefits of composite rollers in terms of reduced downtime, maintenance, and energy costs.

3. Opportunities and Trends

3.1 Technological Advancements in Composite Materials

Ongoing research and development in composite materials promise to make composite rollers even more affordable and efficient. Innovations such as hybrid composites that combine the benefits of multiple materials could lower manufacturing costs while maintaining high-performance characteristics. Additionally, advancements in resin technology, which improve the bonding between fibers and resins, can enhance the mechanical properties and longevity of composite rollers, making them even more attractive for industrial applications.

3.2 Rising Demand in the Renewable Energy Sector

The renewable energy sector, particularly wind and solar power, presents a growing opportunity for the composite roller market. In wind turbine manufacturing, for example, composite materials are widely used due to their strength, lightness, and resistance to environmental factors. As global energy demand shifts towards more sustainable sources, composite rollers used in the production of renewable energy equipment will see increased demand.

3.3 Geographical Expansion

The composite roller market is expected to grow in emerging economies in Asia-Pacific, Latin America, and Africa. As industrialization continues to expand in these regions, the demand for high-performance components like composite rollers will increase. Manufacturers are already expanding their production capabilities in these regions to tap into new markets, driving further growth.

4. Future Outlook

The composite roller market is poised for steady growth as more industries adopt these advanced materials to improve operational efficiency, reduce maintenance costs, and achieve sustainability goals. Despite challenges such as high initial costs and technical limitations, the advantages of composite rollers in terms of durability, performance, and long-term cost savings outweigh these concerns for many end-users.

The future of the composite roller market will likely be shaped by technological advancements that make production more cost-effective, as well as the continued expansion of industries that rely on these high-performance materials. As manufacturers and end-users alike recognize the long-term benefits, the adoption of composite rollers is expected to grow, contributing to a more sustainable and efficient industrial landscape.

Conclusion

The composite roller market is evolving rapidly, driven by the need for better performance and durability in industrial applications. Although challenges remain, the growing demand for energy-efficient and sustainable solutions presents significant opportunities. With ongoing advancements in materials and manufacturing processes, composite rollers are poised to play an increasingly important role across a variety of sectors, shaping the future of industrial equipment.