The semiconductor manufacturing equipment market is experiencing accelerated growth due to the increasing global demand for advanced chips powering everything from smartphones and data centers to electric vehicles and AI systems. As chip complexity grows and new technologies emerge, equipment manufacturers must continuously adapt through well-defined and forward-looking strategies.

Winning in this competitive market requires more than just superior technology—it calls for a comprehensive approach blending innovation, collaboration, and strategic expansion.

1. Innovation-Led Product Development

At the core of every winning strategy in the semiconductor manufacturing equipment space is innovation. As chip architectures evolve and move toward smaller nodes like 5nm and 3nm, the need for precision tools becomes more critical. Leading companies are investing significantly in R&D to develop:

-

Advanced lithography systems

-

High-efficiency etching and deposition tools

-

Automated wafer handling systems

-

AI-powered metrology and inspection equipment

By consistently enhancing their products, manufacturers can address the evolving challenges faced by semiconductor foundries, including yield improvement, defect detection, and energy efficiency.

2. Strong Partnerships and Ecosystem Collaboration

Building a robust ecosystem through strategic partnerships is another winning move. Semiconductor equipment providers are forming alliances with chipmakers, material suppliers, software developers, and research institutions. These partnerships help in co-developing custom tools tailored to the needs of specific processes or customers.

Collaborations also lead to faster innovation, shared risks in R&D investments, and early access to emerging market requirements. This cooperative model ensures equipment providers stay aligned with the technological direction of the semiconductor industry.

3. Global Localization for Resilience

The market is seeing a growing trend of localization to improve supply chain resilience and meet government mandates for domestic manufacturing. Equipment manufacturers are setting up regional service centers, training facilities, and even production lines closer to customer sites in Asia-Pacific, Europe, and North America.

This strategy reduces delivery times, strengthens customer relationships, and minimizes risks from trade restrictions or global disruptions. Localizing operations also helps companies qualify for government support programs and align with national interests in semiconductor independence.

4. Service-Based Business Models

To gain a competitive edge, companies are expanding into value-added services beyond just selling hardware. This includes offering:

-

Long-term maintenance contracts

-

On-site engineering support

-

Software and firmware updates

-

Cloud-based performance monitoring and analytics

This shift toward service-based models allows manufacturers to create continuous revenue streams while building long-term client loyalty. It also helps customers maintain equipment performance, reduce downtime, and extend the lifespan of their tools.

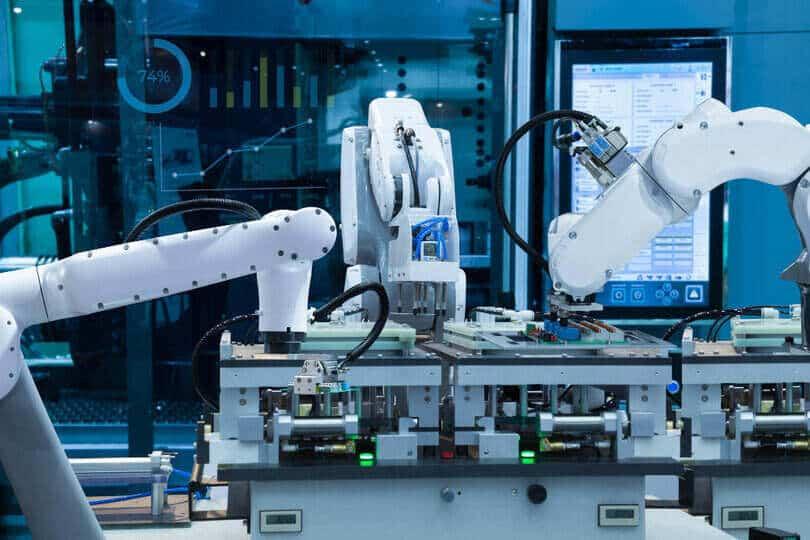

5. Digital Transformation and Smart Manufacturing

Integrating digital tools is a top strategy for winning in today’s dynamic market. Equipment manufacturers are embedding sensors, IoT technologies, and software platforms into their systems to enable smart manufacturing.

Key benefits include:

-

Real-time monitoring of tool performance

-

Predictive maintenance using AI

-

Automated process optimization

-

Remote diagnostics and updates

Digitalization not only enhances product value but also supports fabs in achieving higher yields and faster production cycles—making it a vital differentiator.

6. Expanding Through Strategic Acquisitions

Acquiring complementary businesses is a fast-track strategy to enter new technology segments, gain market share, and enhance capabilities. Strategic acquisitions allow larger players to:

-

Access new customer bases

-

Integrate emerging technologies

-

Expand into underpenetrated markets

-

Increase scale and efficiency

M&A activity also helps companies respond to rapidly changing technological trends by filling gaps in their portfolios and accelerating time-to-market for innovative solutions.

7. Focus on Sustainability and ESG Alignment

Environmental concerns and regulatory pressures are driving equipment manufacturers to adopt sustainable practices. Winning strategies in this area include:

-

Designing energy-efficient tools

-

Minimizing chemical usage

-

Recycling components and materials

-

Reducing carbon emissions at factories

Aligning with global ESG standards not only improves brand reputation but also satisfies increasingly sustainability-conscious clients and investors. Companies that prioritize green innovation are better positioned to thrive in the long term.

8. Talent Development and Skill Advancement

In a highly technical industry, having the right talent is key. Leading firms are investing in workforce training, university partnerships, and upskilling initiatives. This ensures they have the expertise needed to drive innovation, support customers, and keep pace with rapid technological changes.

Developing a culture of continuous learning and technical excellence is a winning strategy that empowers organizations to lead and innovate consistently.

Conclusion

The semiconductor manufacturing equipment market is characterized by rapid innovation, global expansion, and competitive intensity. Companies that stand out are those implementing clear, agile, and forward-thinking strategies. By focusing on technology leadership, strong partnerships, localized operations, service enhancement, digital transformation, and sustainability, equipment providers can position themselves for long-term success.

As the world becomes increasingly reliant on semiconductors, the role of manufacturing equipment will grow even more crucial. The companies adopting these winning strategies will not only survive market shifts—they will shape the industry's future.