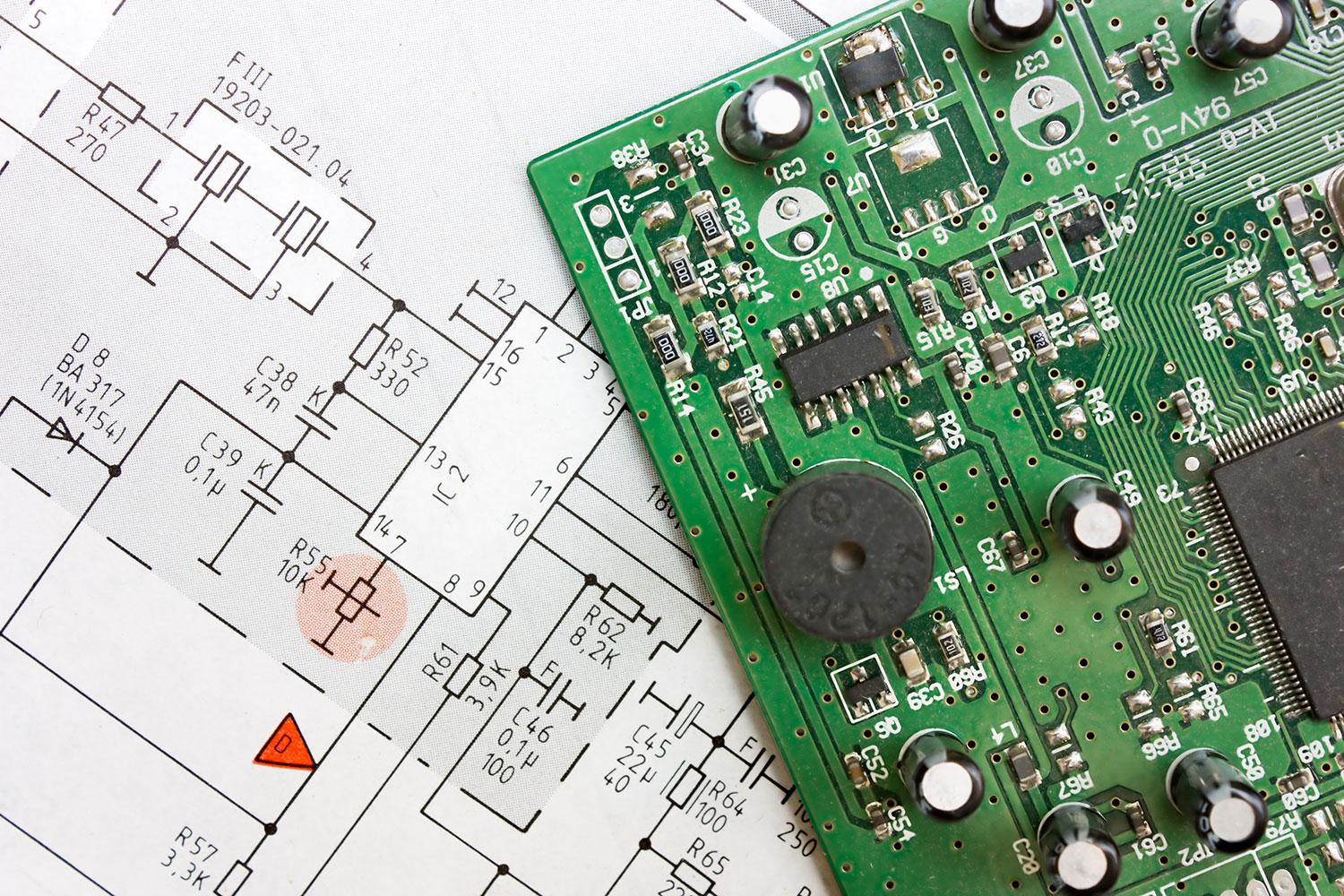

The printed circuit board (PCB) market is an essential part of the global electronics industry, enabling the functionality of virtually all electronic devices. From smartphones and computers to automotive systems and medical devices, PCBs are integral to modern technology. As industries evolve and new technologies emerge, the PCB market continues to experience significant changes, influenced by several factors ranging from innovation and demand shifts to regulatory changes and environmental considerations. In this article, we explore the current market scenario, outlining key trends, challenges, and opportunities in the printed circuit board industry as it looks toward 2025 and beyond.

Current Market Trends

The PCB market has witnessed remarkable growth over the past few years, driven by advancements in technology and the growing demand for electronics. Several key trends are shaping the market scenario:

1. Increasing Demand for Miniaturization and High-Performance PCBs

The demand for miniaturized, lightweight, and high-performance electronic devices is at an all-time high. Smartphones, wearables, IoT devices, and other consumer electronics increasingly rely on smaller, more sophisticated PCBs to fit within compact designs while maintaining high functionality. This trend is fueling the demand for High-Density Interconnect (HDI) PCBs, flexible PCBs, and rigid-flex PCBs, which offer higher performance, greater reliability, and the ability to support advanced features.

2. Advancements in Automotive Electronics

The automotive industry is undergoing a profound transformation, with electric vehicles (EVs) and autonomous vehicles becoming more mainstream. These vehicles rely on complex electronic systems, such as battery management, infotainment systems, and driver-assistance technologies, all of which require advanced PCBs. The growing penetration of electric and autonomous vehicles is significantly expanding the PCB market's scope, particularly in sectors like automotive electronics and electric vehicle (EV) charging infrastructure.

3. Rapid Expansion of 5G and Telecommunications

The global deployment of 5G technology is one of the most impactful drivers for the PCB market. 5G requires specialized, high-performance PCBs to handle high-frequency signals and ensure smooth data transmission. Telecom infrastructure, base stations, and 5G-enabled devices like smartphones, routers, and antennas all rely on advanced PCB designs. This ongoing technological shift is expected to keep driving demand for high-frequency and low-latency PCBs, particularly in emerging markets where 5G adoption is growing rapidly.

4. Growth of Medical Electronics and Healthcare Devices

The healthcare industry has seen a surge in demand for medical devices, from diagnostic equipment and imaging systems to wearable health monitors. As the world embraces digital health technologies, including telemedicine, remote monitoring, and wearable devices, the demand for miniaturized, flexible, and reliable PCBs continues to rise. Medical PCBs must meet stringent regulatory standards while ensuring high reliability and performance. With the increasing trend toward health monitoring systems and telehealth solutions, the medical electronics sector is expected to remain a major contributor to PCB market growth.

Challenges Impacting the PCB Market

Despite the promising growth prospects, the PCB market faces several challenges that could impact its development:

1. Raw Material Shortages and Supply Chain Issues

PCBs require various raw materials, including copper, glass fibers, and epoxy resins. The scarcity of some of these materials, coupled with global supply chain disruptions, has created challenges for PCB manufacturers. Recent events, such as the COVID-19 pandemic and geopolitical tensions, have exposed the vulnerability of supply chains and increased the risk of raw material shortages, which can lead to higher production costs and longer lead times.

2. Environmental Regulations and Sustainability Concerns

With growing environmental concerns and regulatory pressure, the PCB industry is under increasing scrutiny. Manufacturers are required to meet stricter standards on hazardous materials, waste disposal, and energy consumption. As a result, PCB manufacturers are increasingly focusing on sustainability, adopting eco-friendly materials, such as lead-free solder and halogen-free PCBs. However, transitioning to more sustainable production methods comes with its own set of challenges, including higher costs and the need for technological innovation.

3. Increasing Competition and Pricing Pressure

The PCB industry is highly competitive, with numerous manufacturers across various regions, particularly in Asia. While competition drives innovation, it also leads to pricing pressure, especially as the demand for high-quality, low-cost PCBs continues to rise. Smaller manufacturers may struggle to maintain profit margins in the face of intense price competition, particularly when dealing with advanced PCBs that require high precision and specialized materials.

Future Market Prospects

Despite these challenges, the printed circuit board market shows immense potential for growth in the coming years. Several factors are expected to influence the market outlook:

1. Technological Innovations

As new technologies continue to emerge, PCBs will need to evolve. Innovations such as 3D printing and additive manufacturing hold the potential to revolutionize PCB production, enabling faster prototyping, reduced material waste, and greater design flexibility. The integration of AI and machine learning into PCB manufacturing will further enhance efficiency, precision, and quality control, offering new avenues for growth and profitability.

2. Growth in Emerging Markets

As more countries embrace digital transformation, emerging markets present lucrative opportunities for PCB manufacturers. Countries in Asia, Latin America, and Africa are seeing an increase in the adoption of consumer electronics, industrial automation, and telecommunications infrastructure. This growing demand for electronic devices and systems will continue to boost the PCB market in these regions.

3. Shift Toward Automation and Smart Manufacturing

Automation and smart manufacturing technologies are playing a key role in shaping the future of PCB production. The adoption of robotic assembly lines, AI-powered inspection systems, and data analytics is helping manufacturers increase production efficiency, improve quality, and reduce costs. As these technologies become more accessible, they will allow PCB manufacturers to remain competitive while meeting the rising demand for advanced PCBs in various industries.

Conclusion

The printed circuit board market scenario is influenced by a combination of technological advancements, shifting industry trends, regulatory challenges, and global market dynamics. As the demand for miniaturized, high-performance electronics continues to grow, the PCB market is expected to see substantial growth through 2025 and beyond. Manufacturers will need to adapt to challenges such as raw material shortages, environmental regulations, and pricing pressures while embracing new technologies and expanding into emerging markets. By understanding and responding to these dynamics, PCB manufacturers can position themselves for long-term success in a rapidly evolving market.