How Rotary Lobe Pumps Operate in High-Pressure Environments

When it comes to high-pressure environments, having the right equipment can make all the difference. One of the most reliable and effective solutions for such conditions is the rotary lobe pump. These pumps are widely used in various industries for their exceptional performance, especially in handling high-pressure applications. In this article, we will delve into how rotary lobe pumps operate under pressure and why they are indispensable in many industrial settings. We will also discuss their advantages, features, and the role they play in maintaining efficiency and safety.

What is a Rotary Lobe Pump?

A rotary Lobe Pump is a positive displacement pump that uses rotating lobes to move fluid through the system. These pumps are designed to handle a wide range of applications, from low to high-pressure environments. The lobes of the pump rotate inside a housing, creating cavities that expand and contract to displace the fluid, moving it from the inlet to the outlet.

Rotary lobe pumps are favored for their ability to handle viscous fluids, shear-sensitive materials, and materials with high solid content. Their unique design allows them to operate efficiently in environments where other pumps might struggle, particularly in high-pressure settings.

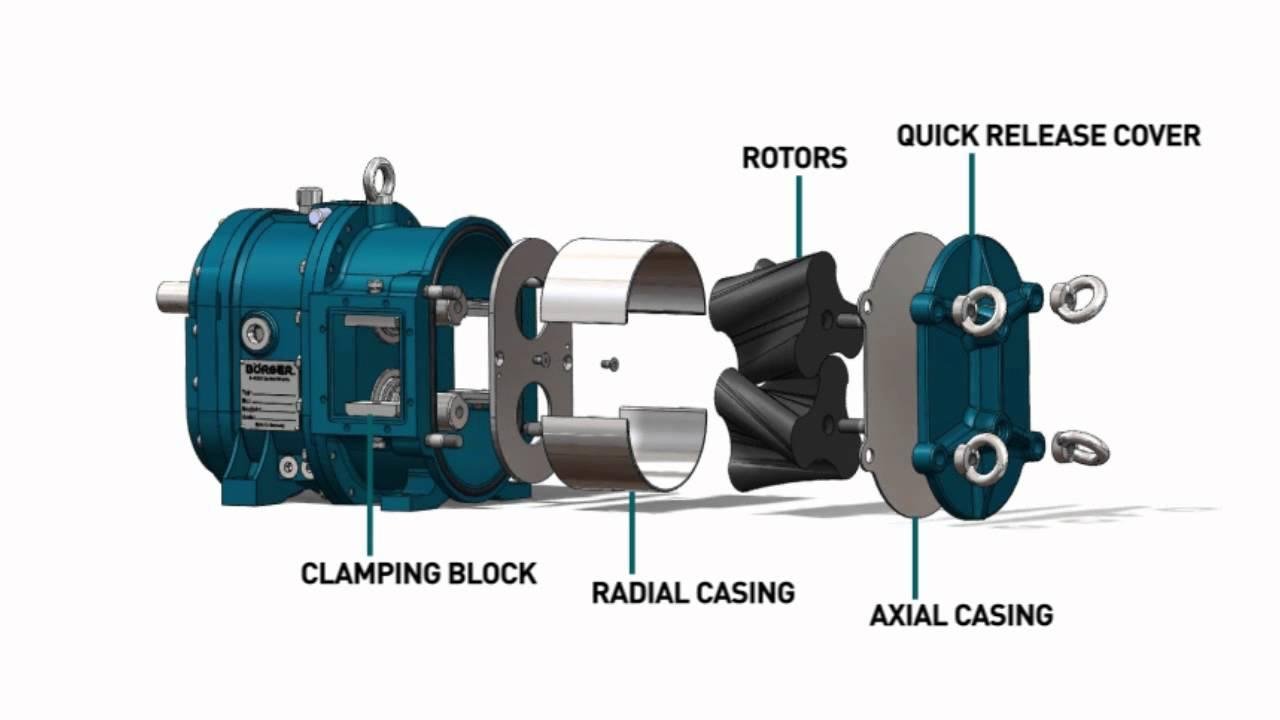

The Design of Rotary Lobe Pumps

The rotary lobe pump design is straightforward yet highly effective in demanding conditions. The pump consists of a few essential components:

-

Lobes: These are the primary moving elements that rotate inside the pump housing. The shape and size of the lobes can vary depending on the application.

-

Rotor Shaft: The rotor shaft connects the lobes to the driving mechanism, typically an electric motor.

-

Pump Housing: This is where the lobes rotate and displace the fluid. It is often designed to withstand high-pressure environments.

-

Seals: High-quality seals ensure that there are no leaks, which is crucial in high-pressure conditions.

One of the key features of rotary lobe pumps is their ability to create a sealed environment inside the pump, preventing fluid from leaking out even when under high pressure.

How Do Rotary Lobe Pumps Work?

The operation of a rotary lobe pump is relatively simple. The lobes rotate inside the pump casing, and as they move, they create a vacuum on the intake side. This vacuum draws the fluid into the pump. As the lobes continue to rotate, the fluid is pushed through the pump and out the discharge side.

The key to the pump's effectiveness in high-pressure environments lies in the tight tolerances and design of the lobes and casing. The design ensures that even under high pressure, the fluid is efficiently moved without causing excessive wear or damage to the pump components. The pump’s positive displacement nature means that it delivers a constant flow of fluid regardless of changes in system pressure.

Factors Influencing Rotary Lobe Pump Performance

Several factors determine how well a rotary lobe pump can perform in high-pressure environments. These include:

-

Lobe Shape and Material: The lobes must be made of materials that can withstand the high pressures and potentially abrasive fluids they are handling. Common materials include stainless steel, which is durable and resistant to corrosion.

-

Pump Size: The size of the pump and the clearance between the lobes and the housing can affect its ability to handle high pressures. Larger pumps can typically handle higher pressures, but they require more power to operate.

-

Seal Integrity: In high-pressure applications, the integrity of the seals is crucial. High-quality seals prevent leaks, ensuring the pump continues to operate at peak efficiency.

-

Speed of Operation: The speed at which the pump operates can affect the pressure it can handle. Slower speeds tend to result in higher pressures, but they can also reduce wear on the pump components.

The Role of Rotary Lobe Pumps in High-Pressure Environments

Rotary lobe pumps are often employed in high-pressure applications where precision, reliability, and consistent performance are crucial. They are ideal for industries such as:

-

Chemical Processing: Many chemicals, especially those that are viscous or have a high solid content, need to be pumped under high pressure. Ace Lobe Pumps are specifically designed to handle such fluids with ease.

-

Food and Beverage: In the food and beverage industry, rotary lobe pumps are used to transfer liquids like sauces, syrups, and other high-viscosity products, all of which need to be pumped under controlled pressure conditions.

-

Oil and Gas: The oil and gas industry requires pumps that can handle high pressures and deal with viscous, thick oils. Ace Lobe Pumps are robust enough to handle such environments.

-

Pharmaceuticals: In pharmaceutical manufacturing, rotary lobe pumps are used for handling delicate liquids, ensuring the product maintains its integrity even under pressure.

Why Choose Rotary Lobe Pumps for High-Pressure Applications?

There are several reasons why rotary lobe pumps are ideal for high-pressure environments. Here are some of the top advantages:

-

Efficiency in High-Viscosity Fluids: These pumps can efficiently handle thick, viscous fluids, which are often encountered in high-pressure settings. They maintain a constant flow rate, ensuring that the system operates smoothly even under varying pressures.

-

Low Shear: The design of rotary lobe pumps ensures that shear-sensitive materials, such as certain chemicals or food products, are not damaged during the pumping process. This is especially important in high-pressure environments where shear can cause product degradation.

-

Self-Priming: Rotary lobe pumps are self-priming, meaning they can operate without the need for external priming systems. This feature is essential in high-pressure environments where the pump may need to start and stop frequently.

-

Durability: The robust design of rotary lobe pumps ensures long-lasting performance in demanding conditions. With proper maintenance, these pumps can operate efficiently for many years.

-

Flexibility: These pumps can be customized for a wide range of applications, making them suitable for various industries that require high-pressure capabilities.

Maintaining Rotary Lobe Pumps in High-Pressure Applications

While rotary lobe pumps are durable, regular maintenance is essential to ensure they continue to perform optimally in high-pressure environments. Here are some maintenance tips:

-

Regular Inspection: Check the seals, bearings, and lobes for signs of wear or damage. In high-pressure applications, any wear can lead to inefficiencies or leaks.

-

Lubrication: Ensure that the pump’s moving parts are adequately lubricated. This reduces friction and wear, particularly under high-pressure conditions.

-

Cleaning: Clean the pump regularly to prevent any buildup of materials, which could affect performance. This is especially important in industries like food and beverage where hygiene is crucial.

-

Monitoring Pressure: Keep track of the pressure levels to ensure they remain within the pump’s operating range. Excessive pressure can cause damage to the pump.

The Future of Rotary Lobe Pumps

As industries continue to evolve and the demand for high-pressure solutions increases, the rotary lobe pump is likely to become even more essential. Innovations in pump materials, efficiency, and design are constantly being developed to meet the needs of industries operating under extreme conditions. Ace Lobe Pumps is at the forefront of this innovation, ensuring that their products continue to meet the ever-growing demands of high-pressure applications.

Conclusion

In high-pressure environments, efficiency, reliability, and durability are key. The rotary lobe pump has proven to be an invaluable tool for industries that require these qualities. From handling viscous fluids to maintaining a constant flow rate, rotary lobe pumps are designed to perform under even the most challenging conditions. Whether in chemical processing, food and beverage, or pharmaceuticals, Ace Lobe Pumps offers solutions that ensure optimal performance and safety. By understanding the operational aspects and maintaining these pumps properly, businesses can enhance productivity and reduce downtime, making rotary lobe pumps a critical component of many high-pressure systems.