From Engine to Epidermis: Why LSR is Gaining Traction Across Industries

Liquid Silicone Rubber’s ability to perform in demanding environments—from medical implants to automotive gaskets—has made it indispensable for modern manufacturing. Its versatility and longevity offer a compelling alternative to thermoplastics and conventional rubbers.

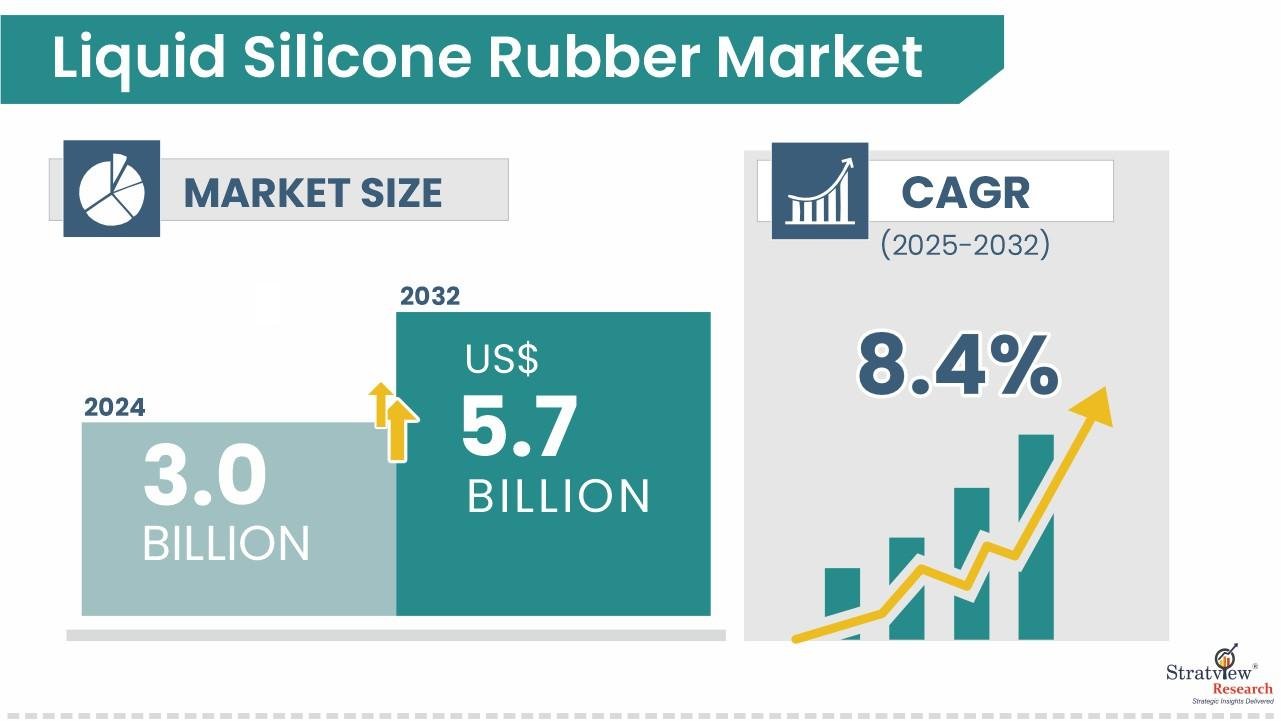

According to Stratview Research, the liquid silicone rubber market was estimated at USD 3.0 billion in 2024 and is likely to grow at a CAGR of 8.4% during 2025-2032 to reach USD 5.7 billion in 2032.

Download the sample report here, to uncover in-depth insights.

https://stratviewresearch.com/Request-Sample/792/liquid-silicone-rubber-market.html#form

Drivers:

- Exceptional Thermal Stability: LSR can function from -50°C to +250°C, ideal for automotive and aerospace.

- Design Flexibility: LSR enables seamless integration into complex and compact product designs.

- Chemical and UV Resistance: Crucial for outdoor and industrial applications.

Challenges:

- Tooling Costs for Prototyping: High cost of precision molds deters low-volume production.

- Cycle Time Management: Some LSR applications still face long curing or molding times.

- Regulatory Compliance: Especially in healthcare and food-grade segments.

Opportunities:

- Electric Vehicles: Demand for vibration-damping, thermally stable materials is growing.

- Reusable Medical Devices: LSR’s reusability and sterilization strength offer sustainable alternatives.

- Consumer Electronics: Smart devices need dust- and moisture-resistant housing.

Trends:

- Growth in transparent and colored LSR grades

- Hybrid manufacturing (LSR overmolded onto metal/plastic parts)

- Surge in customized LSR formulations for niche needs

Conclusion:

Whether protecting sensors or touching skin, LSR’s adaptability gives it a key role in the future of high-performance, human-centric design.