-

أخر الأخبار

- استكشف

-

المدونات

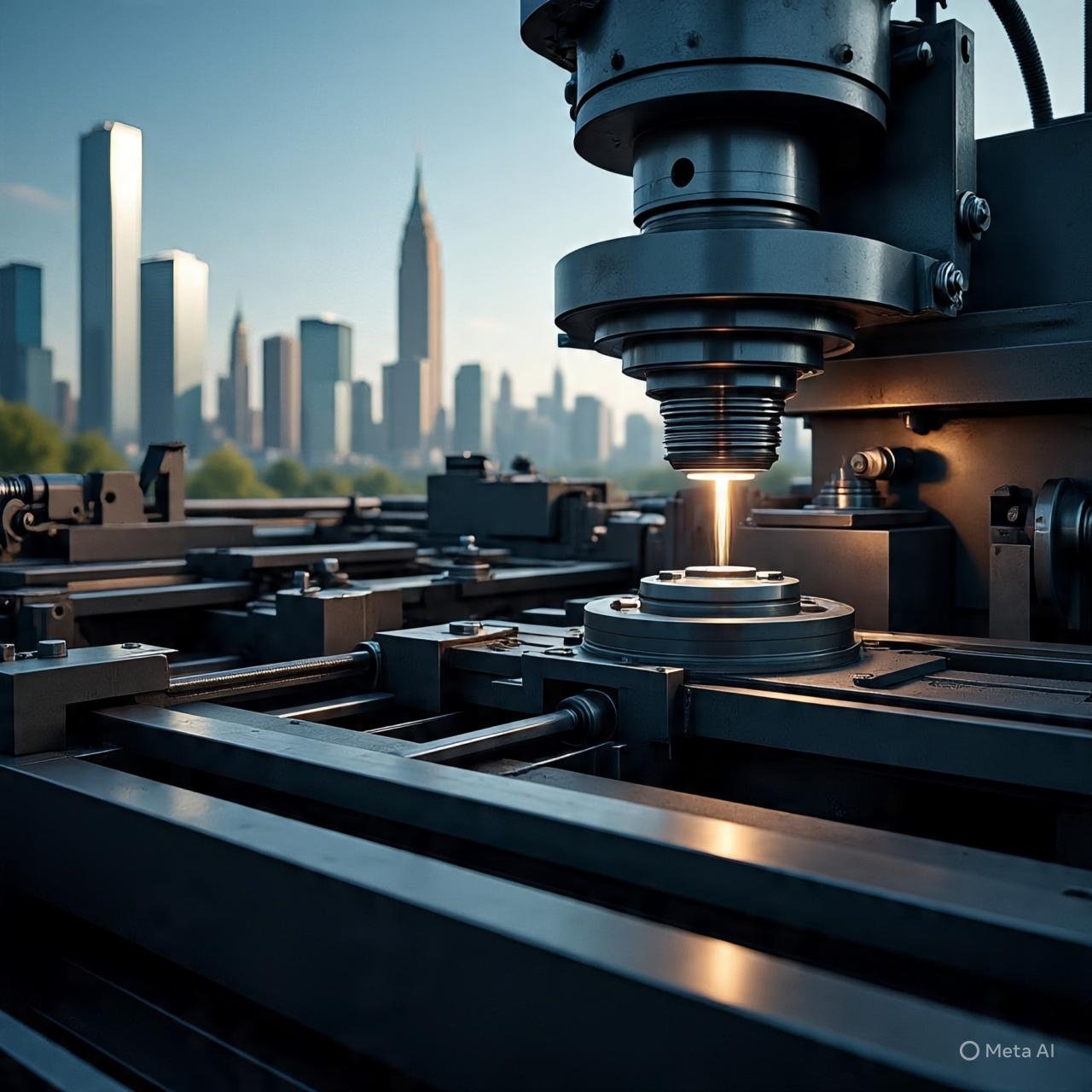

Custom Machined Parts: Precise Solutions for Contemporary Industries

In this day and age of competitive industry, precision and quality can be the make-or-break elements of success. Each part utilized in an apparatus needs to be a precise fit and function correctly. That's where custom machined parts enter the picture crafted and produced specifically to fulfill particular needs with the utmost degree of precision. Aerospace through oil and gas, these unique components are the backbone of contemporary manufacturing. Businesses that depend on Custom Industrial Manufacturing Services recognize that accuracy is not an extravagance, it's indispensable. Every piece manufactured has to not only conform to specifications but also function reliably in stressful conditions.

What Are Custom Machined Parts

Custom machined parts are parts produced via high-technology machining operations such as CNC turning, milling, or drilling, customized to a customer's precise requirements. These components are usually manufactured using high-grade metals like stainless steel, aluminum, or titanium, which provide durability and accuracy. Custom machined components differ from standard or off-the-shelf components since they are specifically designed to meet the specifications of individual applications. Custom machined components are frequently applied in sectors where a slight deviation in size would result in a failure of performance, for example, aerospace, energy, motor vehicle, and heavy equipment. The aim is always the same to attain perfection in each detail to improve efficiency and reliability.

The Role of Custom Industrial Manufacturing Services

Custom Industrial Manufacturing Services play a critical role in the creation of high-precision components that meet the needs of various industries. These services encompass every phase of the manufacturing process, ranging from design and prototyping through to machining, finishing, and inspection. An expert team makes sure that each individual machined component is up to international quality standards and customer requirements. Custom Industrial Manufacturing Companies depend on high-level technology and state-of-the-art CNC equipment to deliver micron-level precision. Their capacity to turn intricate designs into physical components assists businesses in enhancing performance, minimizing downtime, and delivering consistency in their operations. This is the reason precision-oriented manufacturing is one of the most reliable services in industrial manufacturing.

Why Custom Machined Parts Matter

All businesses face their own unique challenges, and the right parts make a difference in how systems perform. Custom machined parts ensure compatibility, strength, and efficiency. Having parts specifically manufactured for an application reduces wear and tear, enhances operation accuracy, and increases equipment lifespan. For instance, in oil and gas, accurately engineered parts are a necessity to manage extreme pressure and temperature levels. In the same way, in the car industry, they enhance performance and vibration reduction. With Custom Industrial Manufacturing Services, companies can guarantee every piece is engineered for its precise purpose, allowing them to preserve safety, performance, and cost-effectiveness.

How Custom Machining Ensures Precision and Quality

Creating custom machined components involves specialized skills, sophisticated machinery, and rigorous quality checks. Manufacturers employ high-end CNC equipment capable of multi-axis machining, allowing intricate shapes to be manufactured with precision. Every component is tested for tolerance, surface finish, and dimensional accuracy before final shipment. This level of detail helps no defect go unchecked. Manufacturers of Custom Industrial Manufacturing Services tend to adhere to global standards such as ISO 9001 in order to remain consistent. They know that accuracy is not solely machine-related; it's people, experience, and an unwavering commitment to excellence. This is the way industries gain dependable performance and long-term value from each and every part they use.

Benefits of Collaborating with a Professional Manufacturer

Collaborating with a professional manufacturer for custom machined parts has numerous advantages. It provides improved quality control, quicker turnaround, and less risk of product failure. A good machining company collaborates closely with customers to determine their precise requirements prior to manufacturing. Through Custom Industrial Manufacturing Services, companies can simplify production, save time, and avoid waste. Such services are flexible whether you require one prototype or large-scale production. UAE manufacturers, such as Genesis MFG, merge advanced machinery with skilled craftsmanship to provide parts that are up to local and international industry standards. Their mission is straightforward: provide precision you can count on every time.

Uses of Custom Machined Parts in Various Industries

Custom machined parts are utilized in almost every contemporary industry. In the oil and gas industry, they are utilized within drilling tools, pumps, and valves. They are essential for the safety of flight in aerospace, but for performance and longevity in the automotive sector. Even in industries such as healthcare and construction, precision parts are important for keeping things running smoothly. Custom Industrial Manufacturing Services provide assurance that every component regardless of use is constructed to operate perfectly under intense conditions. That multi-industry versatility is what gives custom machining a central role in the modern industrial landscape.

Conclusion

Custom machined components form the foundation of industrial production. They deliver the accuracy, durability, and dependability that each process requires to operate optimally. Thanks to reliable Custom Industrial Manufacturing Services, businesses can produce consistent quality and exceptional performance in each project. With a market that expects nothing but perfection, selecting the correct machining partner is crucial. Genesis MFG stands as a trusted name in the UAE, offering world-class machining solutions backed by experience, technology, and quality. From small components to large-scale projects, precision and performance define their work ensuring your operations never compromise on excellence.

FAQs

1. What are custom machined parts used for?

Custom machined parts are used in industries like oil and gas, aerospace, and automotive to ensure precise fit, performance, and durability.

2. Why would I select custom machining versus standard parts?

Custom parts are tailored to your specific requirements, providing improved performance, reduced maintenance, and extended equipment life.

3. What is Custom Industrial Manufacturing Services?

They are turnkey manufacturing services consisting of design, machining, and finishing of precision components made to your specifications.

4. How do manufacturers provide assurance of quality in custom machined parts?

The technology of CNC, sophisticated inspection equipment, and certified procedures are used by manufacturers to ensure accuracy and reliability.

5. What can Genesis MFG do for my machining requirements?

Genesis MFG offers certified Custom Industrial Manufacturing Services in the UAE, providing high-quality machined components designed to perform over the long term.